The heating curve and weather control – all you need to know

March 9, 2020In this article we will discuss the heating curve parameter and how it works with weather control in the central heating boiler.

What is the purpose of using weather control in the boiler – is it worth it?

The previous article discusses the method of boiler control using electronic devices, the so-called automation of the control process.

The main goal of introducing devices that support automatic control is the ability to calculate the values of parameters that are necessary to maintain the appropriate temperature inside the room by reacting to changing external factors.

So you can say that automation in heating system is crucial to:

- The departmental boiler operated more efficiently

- The boiler used less energy – less fuel

- The boiler control was easy and preferably maintenance-free.

- The fact that automatic control is much more convenient for the end user.

- Automatic control do not require expert knowledge.

- Householders do not have to worry about calculating the temperature of water supply in radiators and when to turn it on when they turn off.

What is the role of weather control systems?

The correct setup of parameters for the combustion process is crucial to ensure comfort and optimize the cost of weather conditions for residential premises.

In an ideal heating system, the only input parameter set by the user should be the set temperature inside the room and the selection of all other parameters should deal with the Automatic system.

This action is possible thanks to the use of systems called weather control systems.

The purpose of using such systems is automatic calculation of boiler operation parameters, which include:

- pump operation time

- supply temperature

- pump run-on time

- burner blocking time

- modulation of flame strength

- operating time of the burner

- delta (differental) value of temperature difference at which the boiler switches on

Proper tuning of these parameters by a person who is not an expert and is very difficult and there is a huge risk that it will be working badly, ineffective or even (in extreme cases) it could result in malfunctioning the boiler.

With the help of us comes a weather control system that has an external temperature sensor and often even other sensors such as humidity and wind pressure and is able to select all of the above parameters depending on the changing conditions outside.

For example, if the weather control system detects a sudden change in temperature to a plus and thus the insulation can extend the time of blocking the pump and lowering the set temperature so that the room does not overheat due to previous parameters.

The selection of the optimal parameters of the boiler operation is performed by specialized software which is built into the weather controller .

Why some system fails with automatic weather control ?

Boiler control based solely on the internal thermostat is not ideal.

The systems based on correction-based control perform much better – that is, continuous selection of combustion parameters depending on the changing conditions outside.

Optimal heating means not only providing the set temperature in the shortest possible time, it is also its maintenance so that there is no temperature jump inside the room that is always received negatively by users.

It should also be remembered that heating the boiler is the most expensive energy. It is much better to work on low modulation in the case of condensing boilers because they have the highest efficiency then.

This law is also known from the automotive industry:

We can give this some analogy – economic driving consists in gradually accelerating and releasing cars in a natural way.

The complete opposite situation not-economic driving consists in a very rapid acceleration and the use of the brake in such situations leads to enormous energy losses which are dissipated on the brake pads.

The optimal control of the boiler is very similar.

Leading manufacturers of boilers are trying to create advanced control programs whose purpose is prediction and therefore prediction of heating parameters at the stage of changing weather conditions.

Boiler manufacturers are reluctant to reveal the algorithms with which their products work, but based on the instructions and functions of the heating curve, we are able to draw some conclusions.

Advanced users interested in the subject have come to the conclusion that manufacturers use quite advanced programs that have memory.

In the future, one should expect in the future also algorithms based on machine learning so-called artificial intelligence.

Will will continue this topic in more detailed way with practical examples very soon.

If you are looking for a boiler for your home, you can choose one of our store’s offers. We only offer proven producers you can rely on. Such boilers are an ecological source of heating for your home or office.

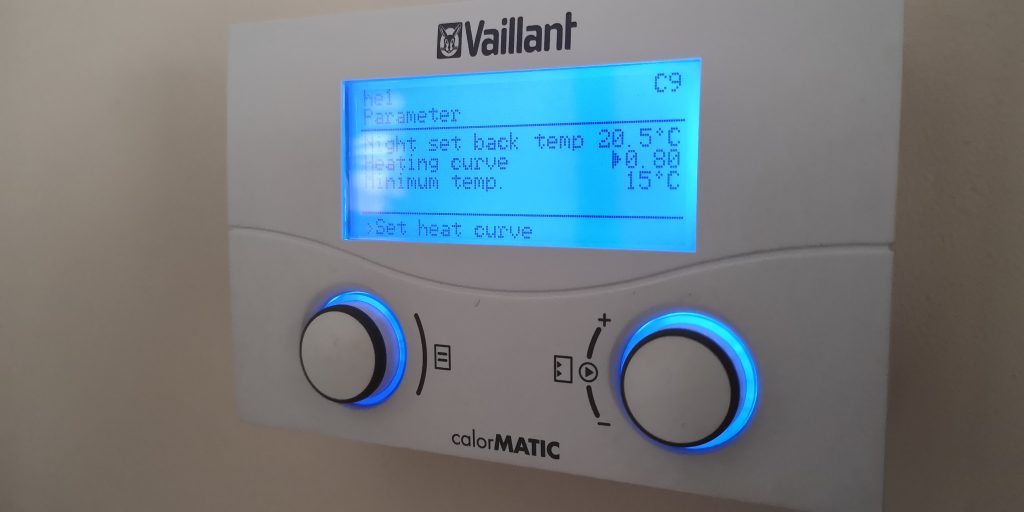

Below is a photo of the Vaillant calorMatic weather controller and the place on the screen where the value of the current heating curve is set.

We will soon prepare a detailed guide for you on how to determine the heating curve for a given installation.

What is the heating curve in condensed boiler?

Now we will discuss what heating curves are and how to interpret them.

Thanks to this tutorial you will be able to understand the purpose of heating curve and tune your heating automation in more efficient way.

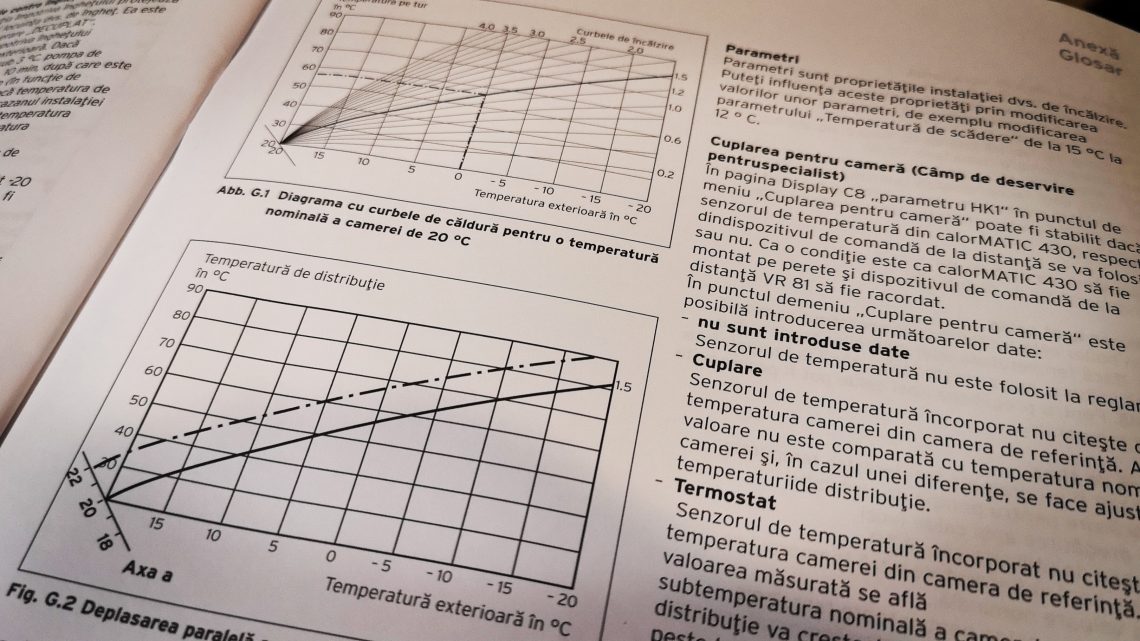

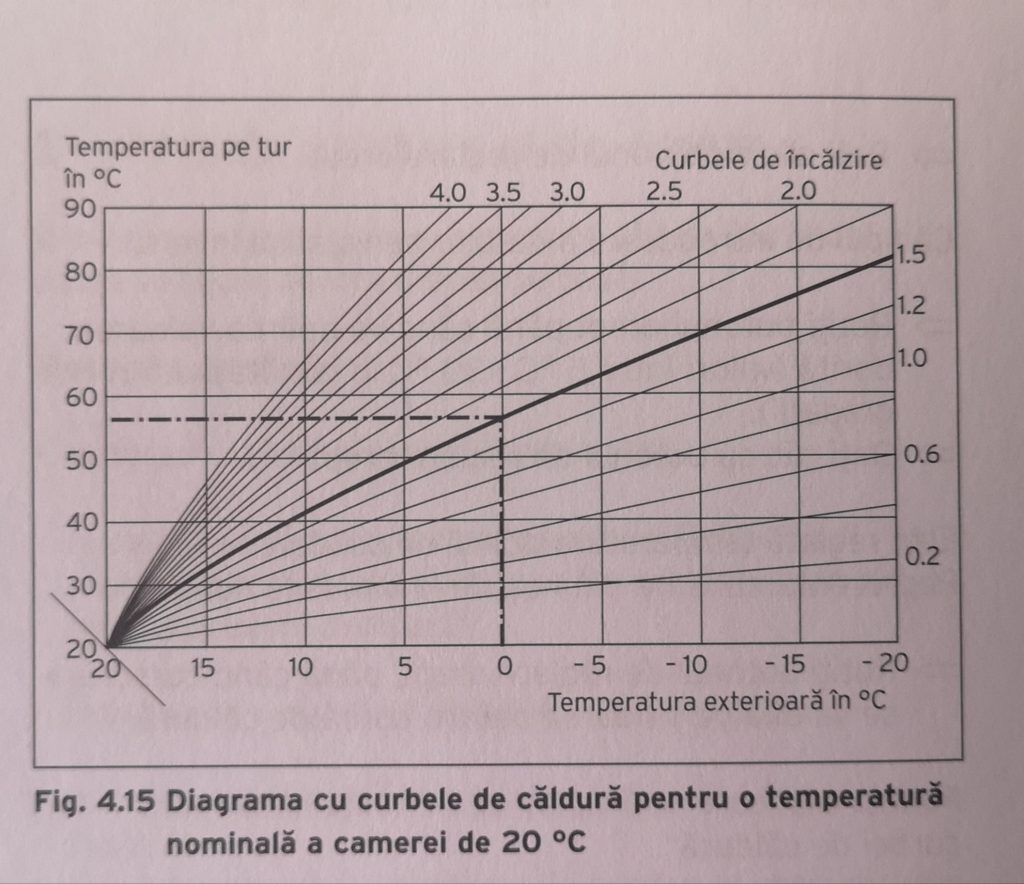

When setting the boiler parameters, we can choose one of many available heating curves. For example Vaillant provides us with settings from 0.2 to 4.0 with 0.1 step.

A single heat curve is a temperature function.

The heating curve can be interpreted as a program for calculating the boiler operating temperature depending on the outside conditions.

In formal terms, the curve expresses the dependence of the supply temperature (hot water that reaches radiators aka the temperature coming out of the boiler) based on the outside temperature.

It worth mention that heat curves set (presented on picture above) is presented for constant inside temperature. If we change the desired temperature inside – some calculations will be done and supply temperature will be altered.

How to interpret the heat curve values in Vaillant eco-Tec boiler ?

Let’s look at the graph above of a selected heating curve with code 1.5.

This curve variant is marked a bold line and it is default heat curve for Ecotec condenser boiler.

For curve 1.5, for a constant internal temperature of 20 degrees Celsius, with an outside temperature of 0 degrees – the boiler will heat the water to a temperature of 58 degrees.

If temperature outside will drop to -10 Celsius degrees – the boiler will heat water to 70 Celsius degrees

In other way,if the outside temperature will be 10 Celsius degrees – the boiler will provide 50 Celsius degrees water and so one.

Why we use heating curve instead of constant heating?

An obvious advantage of using heating based on curves is saving energy and comfor.

When it gets warmer, the boiler will automatically lower the temperature value to which it heats the water in the circuit to prevent overheating.

On the other hand – when it gets cold outside – the curve will show higher temperatures of the heating circuit so that the boiler is able to maintain the temperature set inside.

It is important to choose the curve so that the boiler rarely turns off using the thermostat, or rather works modulating its power thanks to the lower temperatures of the heating circuit.

How to choose the correct heating curve for your home?

The user can choose from many available heating curves, which are shown in the boiler manual.

The default 1.5 curve is medium aggressive which means medium energy profile of the building.

The choice of the heating curve is mainly influenced by the energy efficiency class of the house.

The better insulated the house is – the lower curves can be chosen, for example modern well isolated house can work on 0.6-0.8 curve.

If the building has poor thermal insulation, unfortunately we will have to raise the curve.

Basically, a flatter curve (horizontally) means that the house insulates us well from external conditions. In turn, an aggressively sloping curve is required when the house is very sensitive to low outside temperatures.

Instructions for selecting a curve:

We should strive to make the curve as low as possible – as flat as possible – then we have lower gas bills and better comfort.

However, when we overdo it and lower it too much – we will have a problem with heating the house to the set temperature.

So at the beginning, we choose the low variant, e.g. 1.0, and observe how the boiler works. If several dozen minutes are enough for the boiler to heat the house to the set temperature – it means that it is OK and we could eventually go lower for an experiment.

But if the boiler is still working and cannot heat up our house – we have to raise the curve – because if means that calculated temperature is to low.

Summary

The heating curve allows us to dynamically control the operating temperature of the heating circuit depending on the outside temperature. Well-protected thermally houses work with low curves.

Older houses with inferior insulation or set to midnight – will require a higher curve.

We should always try to work on the lowest possible curve to avoid overheating and switching off the boiler due to the internal thermostat.

Too frequent cycles of heating up and switching off with the thermostat make us feel more cold.

Feel free to ask questions about setting the parameters of the heating curve in the comment section below this article.

[…] Selection of the heating curve level of Vaillant boiler via API (find out more about heating curve) […]